Hard Modeling Peter Verdone Designs

Diametral Pitch Teeth/in. Stndard sizes: 2.5, 3, 4, 5, 6, 8, 10, 12, 16, 20, 24, 32, 40, 48 Pressure Angle: Typically 30, 37.5, or 45 degrees Click on the image below to enlarge Related: AGMA Fine Pitch Tolerances / Quality Grades for Gears Gear Engineering Formulae and Equations Gear Tooth Strength Equations and Calculator

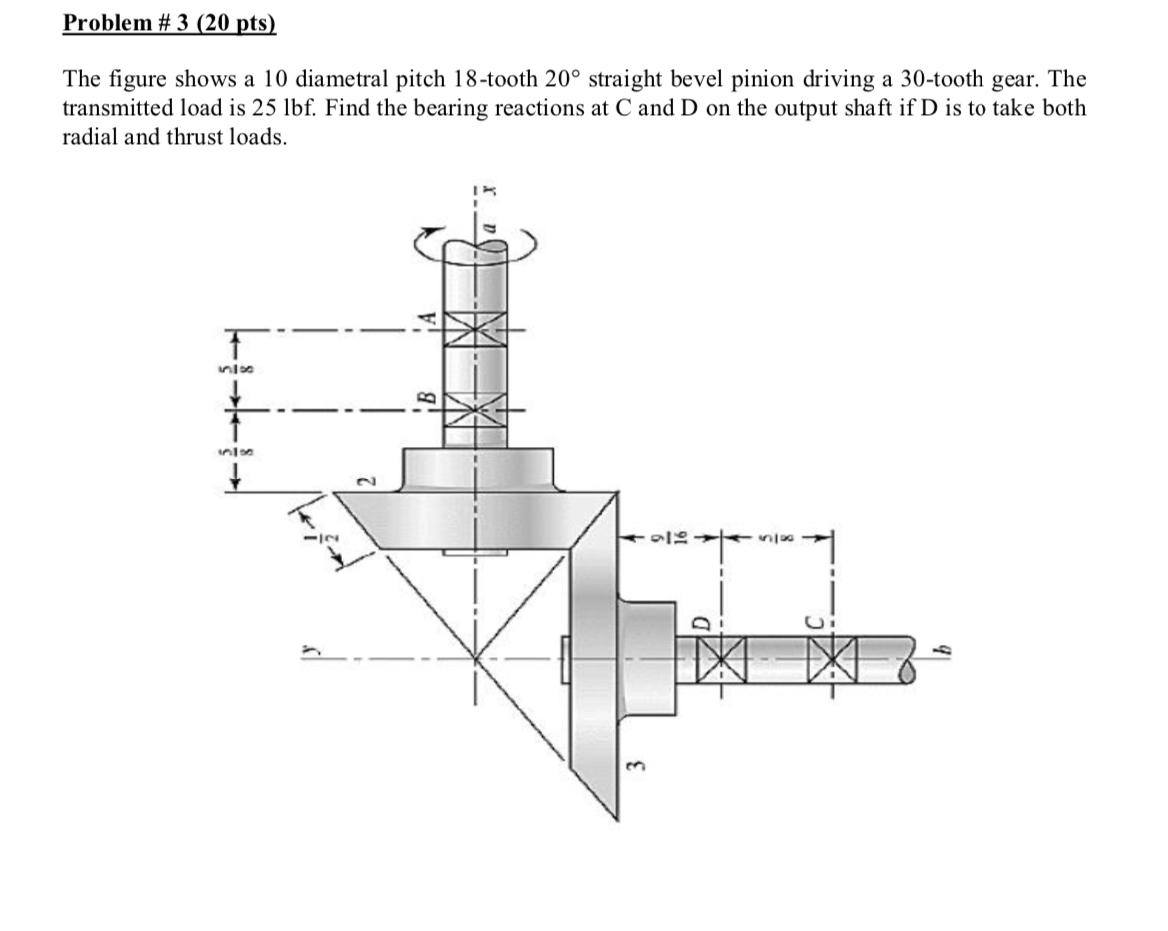

Solved The figure shows a 10 diametral pitch 18 tooth 20∘

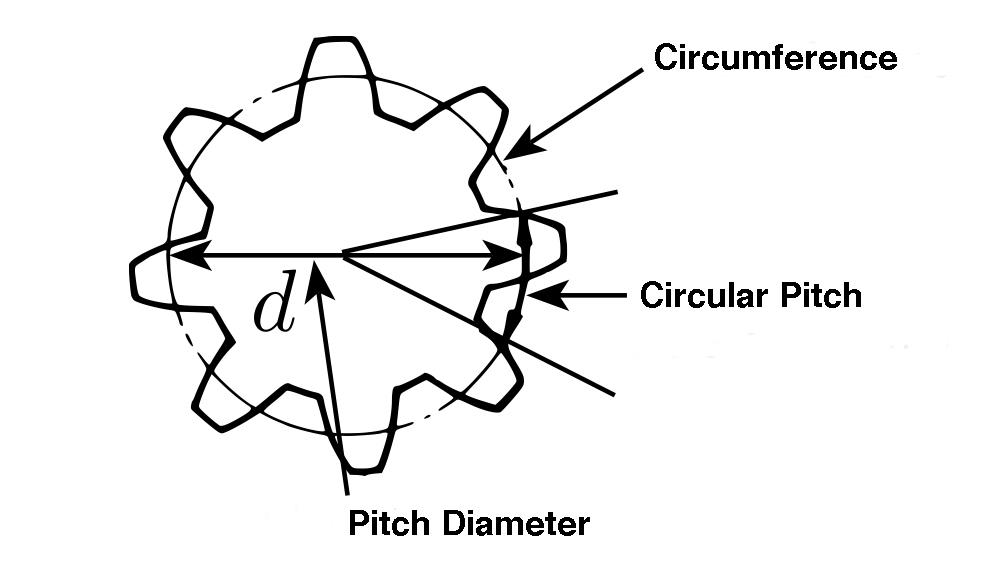

The formula for calculating Diametral Pitch (P) with the well-known Number of Teeth and Pitch Diameter is presented below: where P - diametral pitch, N - number of teeth, D - pitch diameter. In order to calculate the diametral pitch, enter the known value of number of teeth (N), pitch diameter (D) and click the "CALCULATE" button.

Gear Dimensions Calculator Evolvent Design

It is the ratio of the reference diameter of the gear divided by the number of teeth. Module = (Reference Diameter) / (Number of Teeth) m = d / z Diametric, module and circular pitches Conversion. Spur Gear Conversion (Units in inches) Common Gear Pitches by Decimal Size (Units in inches) Gear Pitch Conversion Table Chart (Units in inches) Home

Gears

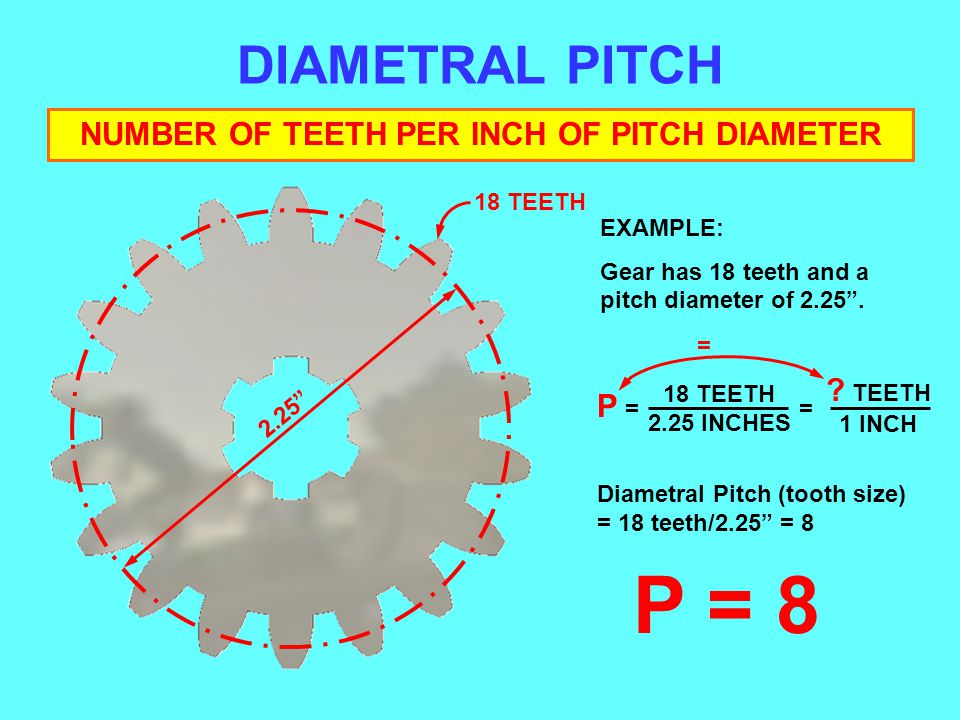

The diametral pitch of a gear describes how densely its teeth are set around it. The pitch is the ratio between the number of teeth and the gear's size, and engineers always express it as a whole number. This value is important for further calculations involving the gear, including the size of each of the gear's teeth.

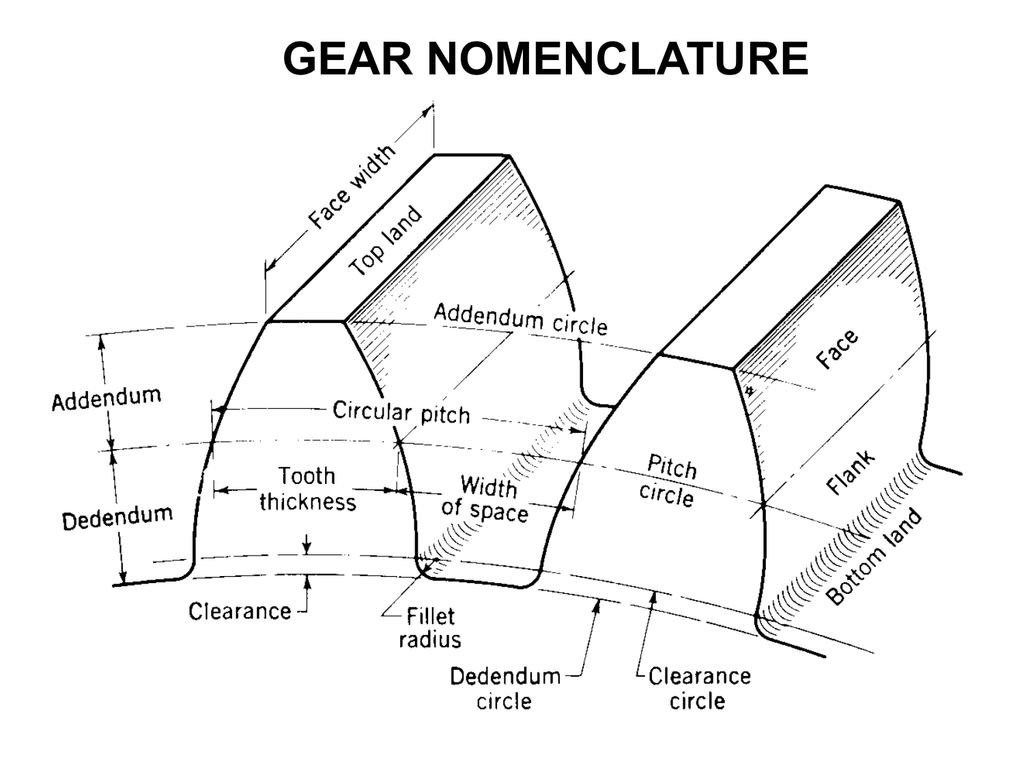

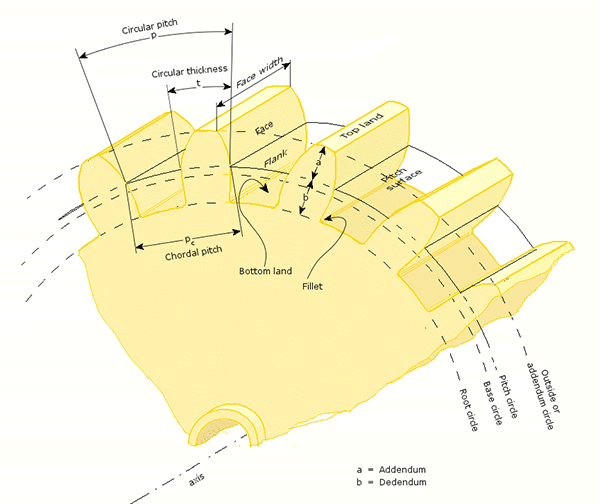

Basic Gear Terminology and Calculation KHK Gears Mechanical engineering design, Mechanical

How to calculate Diametral Pitch given Circular Pitch using this online calculator? To use this online calculator for Diametral Pitch given Circular Pitch, enter Circular Pitch (P c) and hit the calculate button. Here is how the Diametral Pitch given Circular Pitch calculation can be explained with given input values -> 2E+8 = pi/0.016.

Gear Diametrical Pitch Chart Jeff Thompson

Pitch is the distance between a point on one tooth and the corresponding point on an adjacent tooth. It is a dimension measured along a line or curve in the transverse, normal, or axial directions. Diametral pitch is the ratio of the number of teeth to the standard pitch diameter in inches. Related formulas.

GC Sprocket Pitch Diameter Graph

Gear Calculator / Generator I wrote this calculator after getting frustrated with the number of calculators on the web that focus on antiquated diametral pitch based gears rather than modern module gears. To use the calculator, enter the module and number of teeth and the rest of the table should automatically update.

Spur Gear Geometry Picture

The gear rack calculator calculates the key dimensions for a gear rack. Based on the module (or diametral pitch) you can easily get the gear tooth dimensions, including addendum, dedendum, whole depth, tooth pitch, root fillet radius, and more.

Learn How To Easily Fabricate Your Own Gears Make

Gear Pitch Diameter Calculator Calculating gear pitch diameter can be done by dividing the number of teeth on the gear by its diametral pitch. For imperial gears, the Diametral Pitch will generally be an integer ranging from 3 (for very large gears) to 64 (for very small gears). How to Calculate Pitch Diameter of a Gear?

Pitch Diameter Chart1 Building Materials Cutting Tools

Diamond Sketch of Knurling Parameters Pitch Notation TPI Circular TPI* D - Final Diameter * Dw - Wheel Diameter* Db - Blank Diameter G - Material Growth Z -Number of Teeth D - For 29 Teeth D - For 30 Teeth Recomended Cutting Conditions Material Group Cutting Speed In Feed [IPR] Side Feed [IPR] Read Below for detailed technical explanations.

Difference between module and diametral pitch for rack and pinion systems

The diametral pitch (DP) is obtained by dividing the number of teeth (z) by the pitch circle diameter (d, in inches). DP = z / d (inch) In other words, the diametral pitch can be expressed as the number of teeth per 1" inch.

Gear Formula Information Martins Amazing Corrugator Engineering 2023

Gear Dimension Calculator Get all of the dimensions you need to make your gear blank: tip, pitch, root diameters; as well as the gear teeth: addendum, dedendum, working depth, whole depth. External and Internal Spur Gears! Gear Dimension Calculator Center distance calculator Determine how far apart your two gears should be to maintain a proper mesh

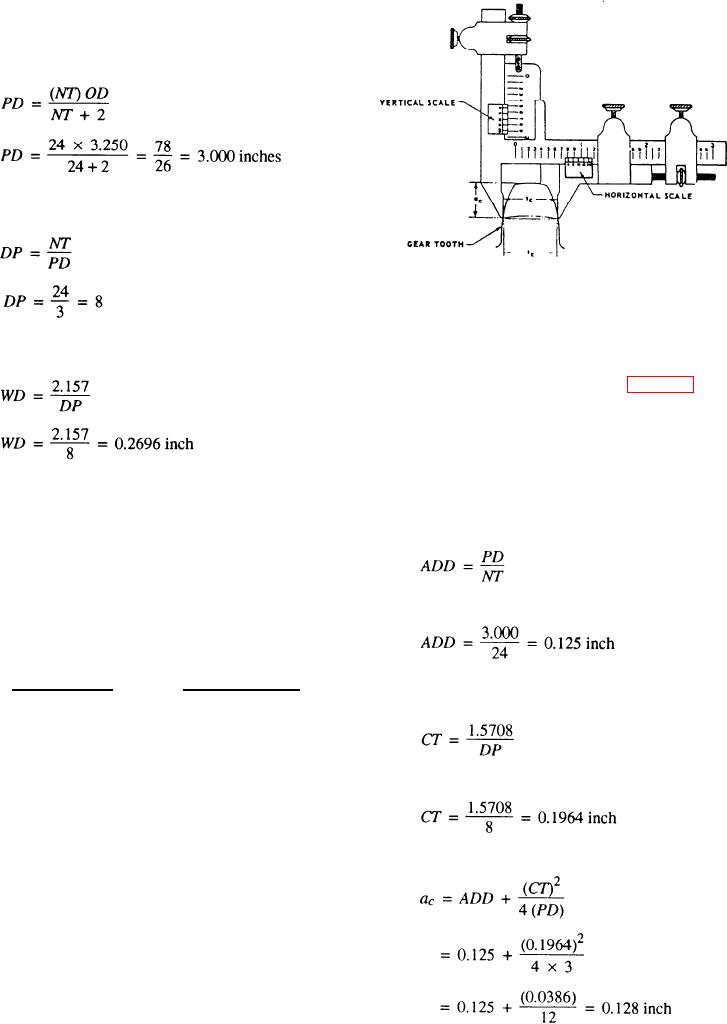

Figure 143.Measuring gear teeth with a vernier caliper.

This pitch diameter calculator will help you find one of the essential dimensions of threaded fasteners - the pitch diameter. In this calculator, you will learn: What pitch diameter is; How to use the metric thread pitch diameter calculator; The different pitch diameter formulas; and How to calculate thread pitch diameter.

32 Diametral Pitch 2 Involute Gear Cutter 7/8 ID 141/2 Degree Pressure Angle

Pitch is the distance between corresponding points on adjacent teeth. p = Pi x Module = πm What is the pitch size (p) of the Gear with module m = 3 ? p = πm = 9.4248 CP (Circular Pitch) Circular Pitch (CP) denotes the reference pitch (p). For instance, you can produce gears at an exact integral value, such as CP5/CP10/CP15/CP20.

Wayyy in over my head AXYZ CNC Router retrofit LinuxCNC

DIAMETRAL PITCH (IMPERIAL) Diametral Pitch is the Number of Teeth to each Inch of the Pitch Diameter. Please note: the above formulae relates to standard outside diameters and pitch diameters. MODULE (METRIC) Module represents the amount of Pitch Diameter (mm) per tooth

12 Diametral Pitch 5 Involute Gear Cutter 1 Inch ID 141/2 Degree Pressure

The formula is as follows: Blank Diameter = ( #Teeth [part] / Diametral Pitch ) American Standard ANSI B94.6-1984 describes the diametral pitch knurl system. Diametral pitch knurls are designed to track uniformly on fractional size stock up to 1" in multiples of 1/32" or 1/64". They are held to closer tolerances for this purpose.